Design Guides

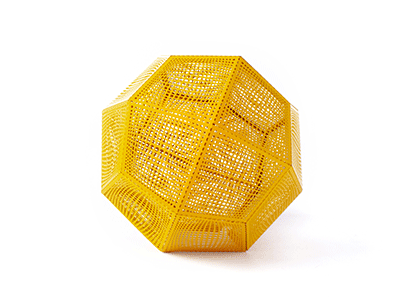

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in stainless steel, aluminum, and other high-performance alloys . DMLS is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve through traditional manufacturing processes. DMLS is often used as a substitution for metal casting. DMLS enables companies to bring products to market they never thought possible with real metal parts and no upfront tooling costs.

DMLS Design Guides

Tolerances: ± 0.5 mm is standard.

Walls: DMLS can manage very thin walls but QSY do not recommend anything under 0.8 – 1mm.Size of single piece can not be less than 10*10*10mm.

Holes & Slots: Minimum 0.5mm gap between axel and bore or other moving parts.

Holes & Slots: We recommend a minimum of 0.5mm but the larger the better especially as wall thickness or depth increases.

Text & Engraved Details: Are at risk of closing up if not designed with 0.5mm > minimum height.

Pins & Embossed Features: Pins ≥ 0.8mm but even then risk breaking. Embossed features ≥ 0.3mm.