QSYrapid: Pioneering Precision and Innovation in 3D Printing

In the rapidly evolving world of 3D printing, Shenzhen Qisiyin Technology Trading Co., Ltd., known as QSYrapid, stands at the forefront, revolutionizing the way businesses approach prototyping and product development. With a rich history spanning 30 years, QSYrapid has cemented its position as a leading 3D printing service provider in China. This article delves into the intricate world of QSYrapid’s 3D printing services, exploring two distinct case studies that exemplify the company’s prowess in transforming conceptual designs into tangible prototypes.

About QSYrapid

Headquartered in the bustling tech hub of Shenzhen, QSYrapid specializes in all-around 3D printing services. The company prides itself on a sprawling12,000-square-meter production facility, buzzing with the activity of over 800 dedicated employees. Housing an impressive array of over 100 3D printers and state-of-the-art post-processing equipment, QSYrapid showcases its commitment to delivering rapid, 24-hour order fulfillment.

At the heart of QSYrapid’s customer-centric approach lies its proprietary online quoting system. This innovative platform provides instant 3D printing price estimates in a mere 3 seconds, revolutionizing the customer experience. Clients can effortlessly upload their 3D/CAD files and receive detailed quotes encompassing material costs, lead times, and more. Moreover, the user-friendly dashboard enables seamless self-service ordering and real-time order tracking, exemplifying the company’s ethos of efficiency and customer empowerment.

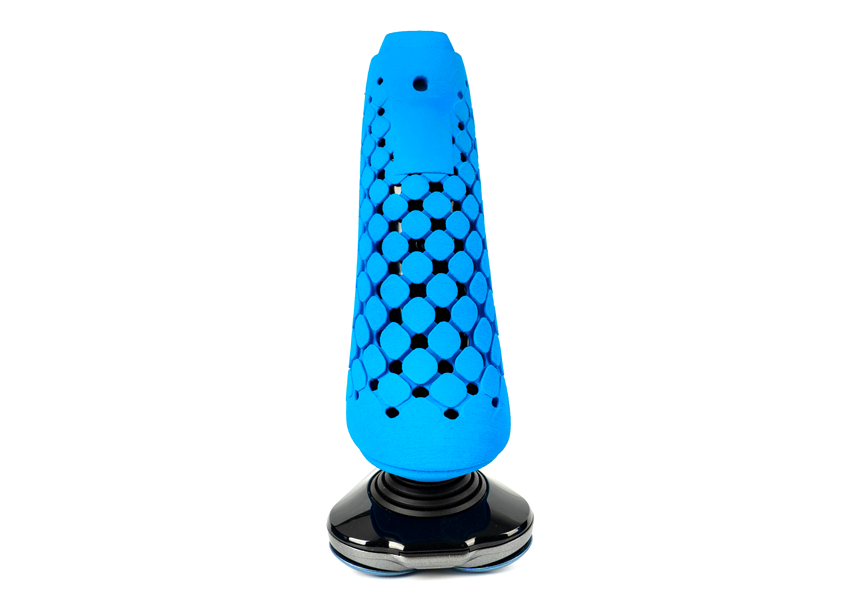

Case Study 1: 3D Printed Electric Shaver Prototype

In the dynamic world of consumer electronics, design updates and iterations are frequent and demanding. QSYrapid’s expertise was put to the test with the development of an electric shaver prototype, a common tool in the daily grooming routine of many. The client’s requirement was not only for a functional prototype but also for an aesthetically pleasing design that would resonate with the end-users.

The prototype in question was for a rotary shaver featuring a unique honeycomb-shaped design for enhanced grip and aesthetic appeal. Leveraging over two decades of experience in prototype production, QSYrapid skillfully navigated the complexities of producing such intricate design elements. The production process employed selective laser sintering (SLS) molding with nylon, ensuring a high degree of precision and fidelity to the original design.

In line with the client’s specifications, the prototype achieved impressive accuracy levels of ±0.1mm, completed within a swift 3-day production cycle. The final product measured 186.56.5cm and underwent meticulous post-processing stages, including polishing, coloring, and varnish application. This case demonstrated not only QSYrapid’s technical capability but also its adeptness in materializing the intricate aesthetic aspects of product design.

The electric shaver prototype was more than just a singular piece; it consisted of multiple parts, each crafted with precision. During production, these parts were separately manufactured according to the client’s detailed drawings, enabling the client to assemble and disassemble the prototype with ease. This modular approach provided an intuitive way for the client to test and verify various product structure and functionality aspects. The result was a visually stunning and highly functional prototype that impeccably mirrored the customer’s design drawings, marking yet another successful endeavor for QSYrapid.

Case Study 2: 3D Printed Electronic Product Camera Sample Prototype

QSYrapid’s versatility in 3D printing was further demonstrated in the second case study, focusing on an electronic product camera sample prototype. The project called for the use of SLA (Stereolithography) curing molding, a process that QSYrapid has refined to near perfection.

The camera sample’s unique requirement was its composition of different materials to achieve specific physical properties. The prototype utilized various types of photosensitive resins, including translucent, black, beige, and white, forming a versatile material group frequently employed in design samples.

This project was a perfect illustration of QSYrapid’s capability to blend different 3D printing materials and processes. One part of the camera was printed using translucent resin material via the SLA process, while the other half utilized Lasty-R, a non-transparent yellow part. The blend of these materials not only demonstrated QSYrapid’s efficiency and proficiency in 3D printing but also highlighted the company’s capacity to cater to diverse material requirements.

Post-processing played a crucial role in this project, especially for the rear half of the component, which required additional steps to achieve the desired outcome. The final effect was attained through a meticulous process of polishing, followed by spraying with silver oil, creating a sleek, professional finish. The camera prototype showcased a multitude of transom parts, achieved through 3D printing – a testament to QSYrapid’s ability to produce intricate designs rapidly, more efficiently, and at a lower cost compared to traditional CNC methods.

QSYrapid: The Epitome of 3D Printing Excellence

QSYrapid’s continuous investment in cutting-edge 3D printing technology has equipped the company with a diverse array of technologies and materials, cementing its status as a pioneer in the field. The company’s fleet includes over 80 industrial SLA 3D printers, more than 20 SLS nylon laser sintering systems, 20+ SLM metal 3D printers, and 10 FDM printers. This robust lineup enables QSYrapid to cater to a wide range of applications, from conceptual models to functional manufacturing, delivering print quality and tolerances as precise as ±0.1mm.

Over its 30-year journey, QSYrapid has become a trusted partner for leading companies across various industries, such as automotive, aerospace, appliances, lighting, robotics, and architecture. Its collaborations with giants like Xiaomi, Tencent, DJI, Huawei, Estée Lauder, Audi, and Airbus are a testament to its unparalleled expertise and ability to meet the most demanding industry standards.

Final Words

QSYrapid’s journey from a pioneering startup to a leading 3D printing service provider is a narrative of relentless innovation, customer-centric solutions, and technological mastery. With its customer-first approach, advanced technologies, and rigorous quality control processes, QSYrapid stands as the premier partner for businesses venturing into the world of additive manufacturing. As 3D printing continues to revolutionize product development across industries, QSYrapid is perfectly positioned to provide the platform and expertise necessary for businesses to unlock innovation and stay ahead in the market.

Should you have any interest in what 3D printing can do for your businesses and what we are capable of at your service, don’t hesitate to contact us today!

Read More

- Get the most out of custom part sourcing with our comprehensive guides to digital manufacturing. Perfect for designers and engineers.

- 3D Printing Price: An Introduction to Rapid Prototyping Services

- Revolutionize Your Business with Rapid Prototyping Services from QSYrapid | QSYrapid

- QSYrapid: Pioneering Precision and Innovation in 3D Printing•https://www.qsyrapid.com

- Introduction to Rapid Prototyping Services | QSYrapid