PLA

PLA (Polylactic Acid) is a bio-based, biodegradable thermoplastic polyester widely used in 3D printing, packaging, medical fields, and more.

Features: Eco-friendly and easy to print,Moderate strength

Processes: FDM

Typical Applications: Educational models, creative prototypes

ABS

ABS (Acrylonitrile Butadiene Styrene) is a commonly used thermoplastic engineering plastic, with its characteristics derived from the synergistic effects of its three monomers.

Features: Impact-resistant, polishable with acetone

Processes: FDM/SLS

Typical Applications: Functional components, automotive interiors

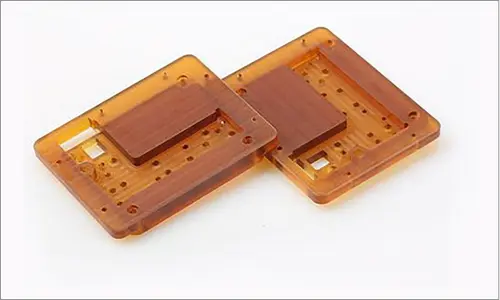

RESIN

Resin refers to a category of synthetic or natural high-molecular-weight compounds that transition from a liquid to a solid state through a curing reaction. In industry, it typically denotes engineering resins (such as epoxy resin, polyurethane resin) or 3D printing photopolymer resins.

Features: Eco-friendly and easy to print,Moderate strength

Processes: FDM

Typical Applications: Educational models, creative prototypes

NYLON

Nylon is a synthetic polymer belonging to the polyamide (PA) family, known for its high strength, toughness, and chemical resistance.

Features: High strength, wear resistance, design freedom

Processes: SLS/MJF

Typical Applications: Typical Applications: Industrial parts, aerospace, medical, consumer goods, etc.

PETG

PETG (Polyethylene Terephthalate Glycol-modified) is a commonly used 3D printing material that combines the ease of printing of PLA with the toughness of ABS, while offering superior chemical resistance, impact resistance, and transparency.

Features: High impact resistance (better than PLA), moderate rigidity, and good wear resistance. Semi-transparent, with improved light transmission achievable by increasing layer height and printing at slower speeds.

Processes: FDM

Typical Applications: Functional prototypes, packaging design, medical devices, etc.

TPU

TPU (Thermoplastic Polyurethane) is a block copolymer composed of soft segments (polyether or polyester) and hard segments (diisocyanate and chain extenders).

Features: High elasticity, tear resistance, and wear resistance. Resistant to oil, solvents, and hydrolysis. Some TPUs are biodegradable or recyclable.

Processes: SLS/FDM

Typical Applications: Flexible components, industrial parts, consumer goods, etc.

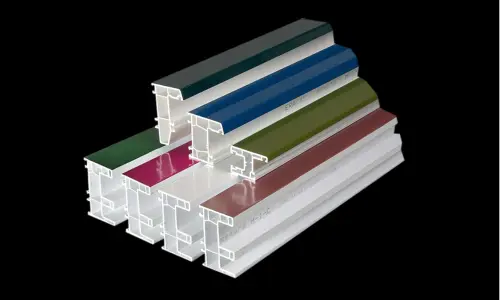

ASA

ASA Material (Acrylonitrile-Styrene-Acrylate Copolymer) is a weather-resistant engineering plastic commonly used for outdoor 3D printed products (such as automotive parts, outdoor decorations, etc.).

Features: UV-resistant, moisture- and heat-resistant, maintains color stability without yellowing or embrittlement during long-term outdoor use. Resistant to weak acids, alkalis, greases, and alcohols. Can be sanded and painted, easily achieving a smooth surface.

Processes: FDM

Typical Applications: Outdoor functional components, architectural and landscape models, industrial prototypes, etc.

PEI

PEI (Polyetherimide) is a high-performance thermoplastic engineering plastic known for its excellent high-temperature resistance, mechanical strength, chemical stability, and flame retardancy. Its glass transition temperature (Tg) is approximately 217°C, with a long-term service temperature of up to 170°C or higher, making it suitable for high-temperature applications.

Features: High-temperature stability and dimensional stability.

Strong interlayer adhesion: Minimizes cracking risks during FDM printing due to excellent layer bonding.

Surface smoothness: Can be improved through polishing or vapor smoothing.

Processes: FDM

Typical Applications: Aerospace, automotive, electrical & electronics, medical, and industrial molding.