ABS

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer formed by the copolymerization of three monomers: acrylonitrile (A), butadiene (B), and styrene (S).

Features:

Mechanical Properties: High strength, impact resistance, and wear resistance.

Chemical Resistance: Resistant to weak acids, alkalis, and oils.

Processability: Easy to mold, extrude, and 3D print (e.g., FDM technology).

Others: Can be electroplated or painted, but has poor weather resistance (susceptible to UV degradation).

Applications:

Automotive parts, appliance casings, toys, consumer electronics, etc.

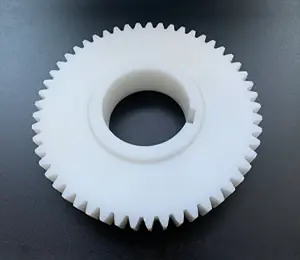

POM (DELRIN)

POM (Polyoxymethylene) is a high-performance engineering plastic.

Features:

High rigidity & wear resistance: Mechanical strength close to metal, suitable for enduring repeated friction.

Low friction coefficient: Excellent self-lubricating properties, requiring no additional lubrication.

Chemical resistance: Resistant to oils and solvents, but susceptible to corrosion by strong acids and alkalis.

Dimensional stability: Low water absorption, minimal deformation under humid or temperature-varying conditions.

Processability: Easy to mold and extrude, but with a narrow melting temperature range (approx. 175–200°C).

Applications:

Gears, bearings, automotive components, electronic parts, etc.

PC (POLYCARBONATE)

PC is a thermoplastic engineering plastic known for its high strength, transparency, and heat resistance.

Features:

Mechanical Properties: High impact resistance (250 times that of glass), good wear resistance.

Optical Properties: Light transmittance up to 90%, close to that of glass.

Temperature Resistance: Long-term service temperature range of -40°C to 120°C, with short-term tolerance up to 135°C.

Chemical Stability: Resistant to oils and weak acids, but not resistant to strong alkalis and certain organic solvents.

Electrical Insulation: Suitable for electronic components.

Applications:

Safety helmets, bulletproof glass, medical devices, CDs/DVDs, automotive lamp covers, etc.

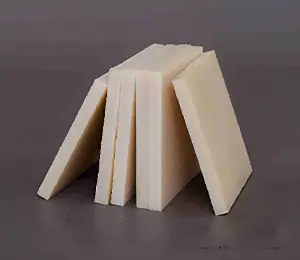

PA (NYLON)

Nylon is a synthetic polymer belonging to the polyamide (PA) family, known for its high strength, wear resistance, and chemical stability. In 3D printing, nylon is a popular material due to its excellent mechanical properties and processability.

Features:

Mechanical Performance: High strength, excellent wear and impact resistance, and good toughness.

Thermal Performance: Relatively high melting point (e.g., 220°C for PA6, 260°C for PA66), capable of withstanding short-term high temperatures.

Chemical Stability: Resistant to oils and solvents but prone to moisture absorption (requires drying before processing).

Processability: Can be formed through injection molding, extrusion, or 3D printing (e.g., selective laser sintering, SLS).

Applications:

Automotive parts, electronic housings.

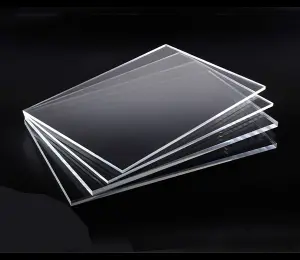

PMMA (ACRYLIC)

PMMA (Polymethyl Methacrylate), commonly known as acrylic or plexiglass, is a transparent thermoplastic polymer.

Features:

High transparency: Light transmittance up to 92%, superior to ordinary glass.

Lightweight & durable: Low density (1.18 g/cm³) with better impact resistance than glass.

Excellent processability: Easy to cut, engrave, injection mold, and thermoform.

Weather resistance: UV-resistant, less prone to yellowing in outdoor applications.

Drawbacks: Lower hardness (scratches easily) and moderate heat resistance (softening point around 80–100°C).

Applications:

Medical devices, automotive industry, consumer electronics.

PEEK

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic specialty engineering plastic known for its exceptional mechanical properties, high-temperature resistance, chemical stability, and wear resistance.

Features:

High-Temperature Resistance: Long-term service temperature up to 250°C, with short-term tolerance exceeding 300°C.

High Strength & Rigidity: Mechanical properties close to metals but with lighter weight.

Chemical Corrosion Resistance: Highly resistant to most organic solvents, acids, alkalis, and oils.

Wear Resistance & Self-Lubrication: Low friction coefficient, ideal for high-wear environments.

Electrical Insulation: Excellent dielectric properties, suitable for the electronics and electrical industries.

Biocompatibility: Applicable in medical implants (e.g., orthopedics, dentistry).

Applications:

Aerospace (metal component replacements)

Automotive Industry (high-temperature gears, bearings)

Medical (surgical instruments, implants)

Electronics (insulating components)

Petrochemical (corrosion-resistant seals)

PP (POLYPROPYLENE)

PP is a thermoplastic polymer made from the polymerization of propylene monomers and belongs to the polyolefin family. It exhibits high chemical stability, with resistance to acids, alkalis, and organic solvents (at room temperature), but is susceptible to erosion by strong oxidizing agents.

Features:

Low cost, short cycle time, lightweight, corrosion-resistant

Applications:

Prototype validation, small-batch production, low-cost substitution

PE (POLYETHYLENE)

Polyethylene (PE) is a thermoplastic polymer made from the polymerization of ethylene monomers. It is currently one of the most widely produced and extensively used plastics.

Features:

Chemical resistance

Excellent electrical insulation

Low cost

Easy to process

Applications:

Product development verification

Small-batch trial production

Low-cost, flexible manufacturing