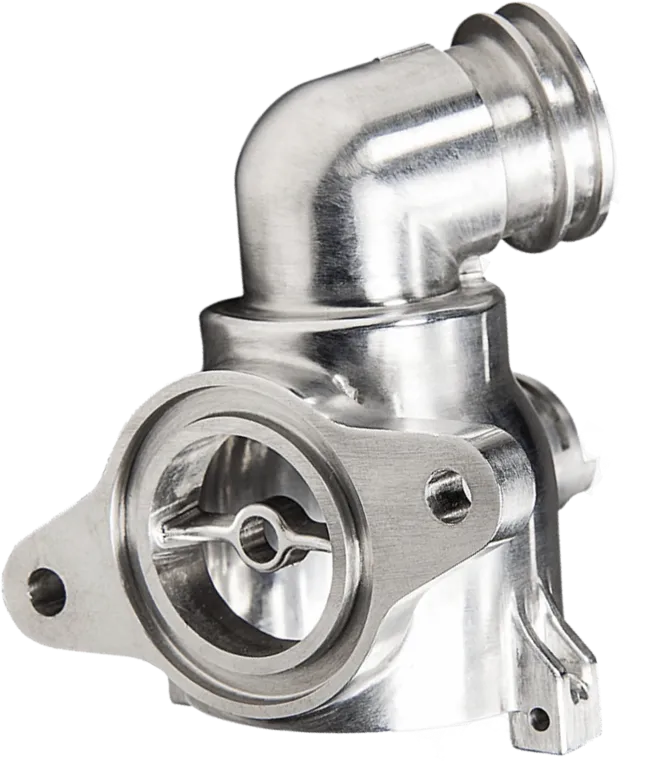

With the advancement of smart manufacturing, CNC machining centers are now integrating with robotics, 3D printing, and other technologies to build flexible production lines. From prototyping to large-scale production, CNC technology continues to deliver precise and efficient manufacturing solutions, solidifying its role as an indispensable core competency in high-end manufacturing.

Workpiece rotation with linear tool feed

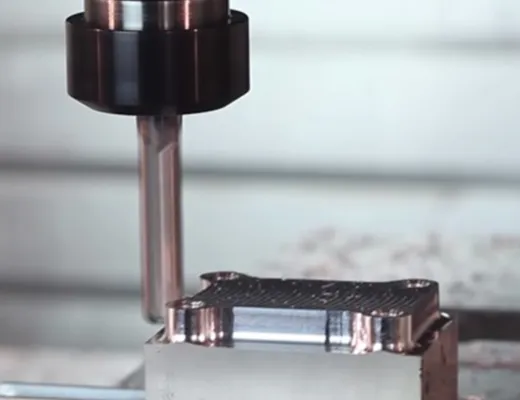

Primarily processes rotational parts Capable of external cylindrical, internal bore, face, and thread machining